Department Process Engineering

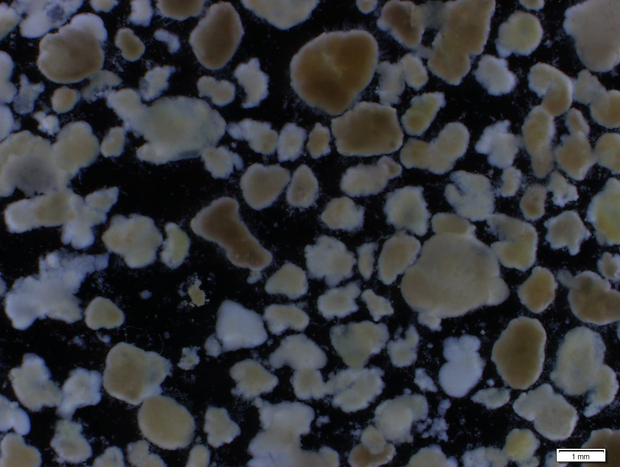

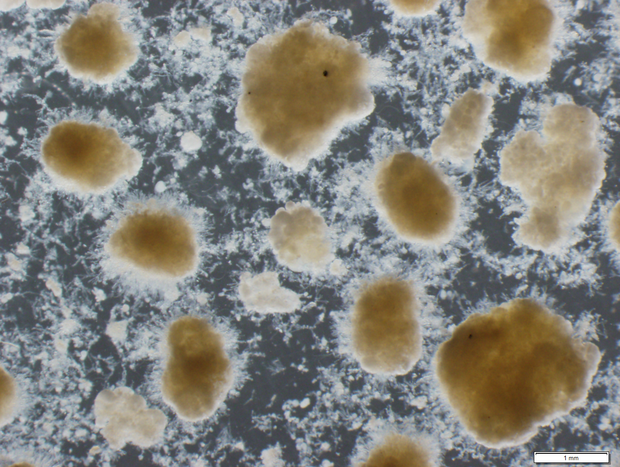

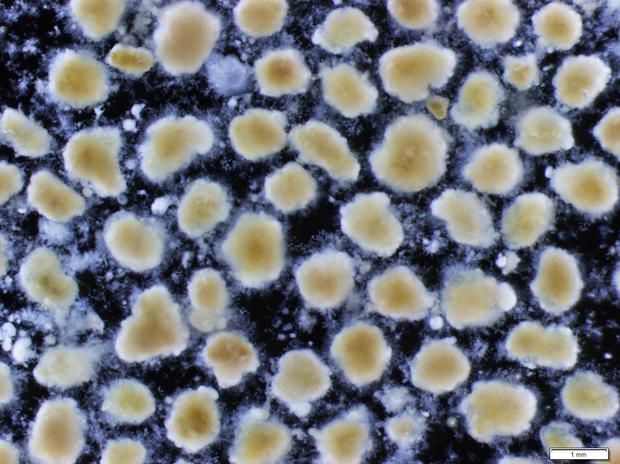

Aerobic Granular Sludge

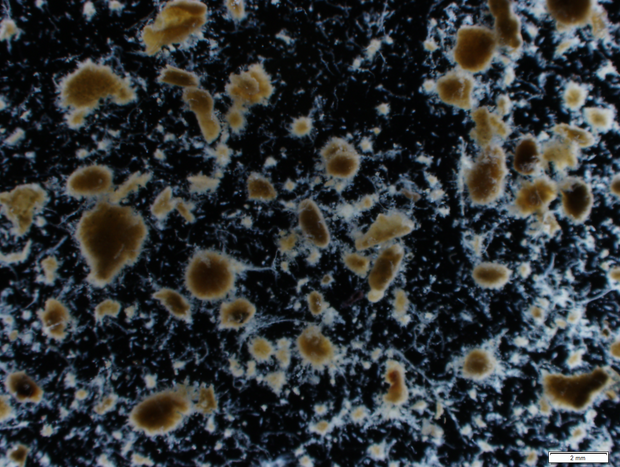

Aerobic granular sludge (AGS) systems have been developed over the past 25 years and now offer a relevant alternative over conventional activated sludge systems. Worldwide, more than 70 full-scale plants are now in operation or under construction based on sequencing batch reactors (SBR), treating a wide range of municipal and industrial wastewaters. In theory, the advantages of AGS include enhanced settling properties, a high suspended solid concentration and the co-existence of different redox conditions across the granules, which result in significant energy, footprint and chemical savings. Our research mainly aim at advancing our understanding of granule formation during treatment of municipal wastewater and at critically evaluate the performances of AGS systems over other biological treatment processes.

Research on granules formation

Our research aims at advancing our fundamental understanding of granule formation. Especially, our research on AGS aims at understanding:

- the link between the influent composition in terms of VFAs and particulate organic substrate, the granulation and resulting granule's properties (size, fraction of granules, setteability), and ultimately the performances of AGS systems.

- the fate of organic substrates during SBR operation (storage, fermentation, hydrolysis, anoxic or aerobic oxidation) and its impact on the nitrogen removal (simulatenous nitrification-denitrification and total nitrogen removal).

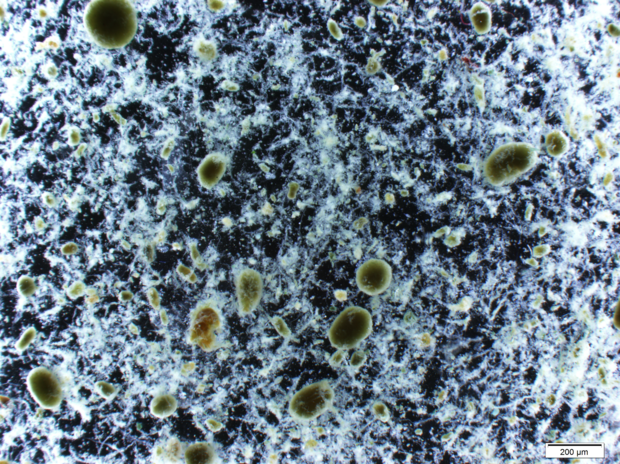

- the role of "flocs" (materials smaller than 250 µm) of the AGS.

- the green-house gas emissions of AGS systems, e.g., N2O emissions.

Aerobic granular sludge in practice

Eawag had been involved in several pilot-scale and full-scale studies with both national and international industrial partners:

- pilot-scale study of the Nereda technology at the WWTP of Kloten-Opfikon, CH, in collaboration with Wabag and DHV RoyalHaskoning.

- pilot-scale study the Nereda technology at Kompetenzzentrum Wasser Berlin.

- full-scale study of the WWTP of Sarnerataal Alpnach.

Modelling of AGS systems

Eawag has been developping a new model of AGS systems to help understanding those systems and support engineers in the design, failures identification or optimization. Please visite the project page of the Eawag Complex AGS model: https://www.eawag.ch/en/department/eng/projects/abwasser/ags-aerobic-granular-slugde-model/ .

Resource recovery from Aerobic Granular Sludge?

Alginate-Like Exopolymers are a mixture of biopolymers extracted from the extracellular polymeric substances (EPS) matrix of bacterial aggregates, such as AGS. ALE can then be used to form hydrogels that can be further reused for the recovery of phosphorus. Part of our research aims at evaluating to what extent can ALE be recovered from AGS and further used for the recovery of phosphorus.

Publications

Alumni

- Manuel Layer (PhD student, 2016-2020)

- Cassio Moraes Schambeck (PhD student in co-supervision, 2016-2020)

- Matthias Staehle (Master student, 2020)

- Mercedes Garcia Villodres (Master student and then research assistant, 2017-2018)

- Mengjiao Xing (Master student, 2018)

- Kristina Bock (Master student, 2018)

- Jamile Wagner (PhD student in co-supervision, 2012-2016)

- Antonio Hernandez (Master student, 2017)

- Eva Reynaert (Master student, 2017)

- Michael Cunningham (Master student, 2015)

- Ueli Thalmann-Müller (Master student, 2013)