Department Urban Water Management

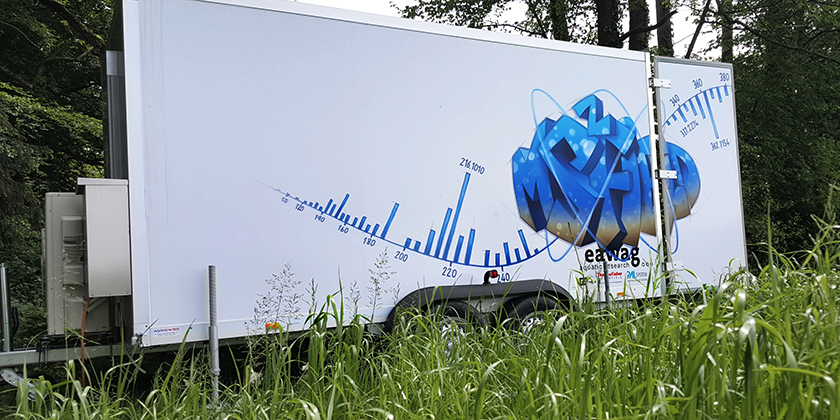

MS2field

Next challenge: Measuring at combined sewer overflows

September – December 2021. The time has come for MS2field to take on new challenges. This time a particularly difficult task awaits: measuring contamination in combined sewer overflows (CSOs) as part of the mikroMISCH project . CSOs are those points in the sewer system where, during rain events, the wastewater is discharged untreated into the river in order to protect the treatment plant from excessive amounts of water. The special thing about this measuring location is that the MS2field has to automatically start with measuring when rain events occur and has to cope with raw wastewater, which can be full of surprises (especially solids). Thanks to the upgrade with a clean water tank and level probe, the MS2field was able to cope with these requirements and measured reliably during rain events. The acquired data gives insight into the temporal dynamics of a wide spectrum of organic micropollutants during the discharge events. This should help to better assess the ecotoxicological influence of CSOs on the receiving water bodies and to suggest possible measures to improve the situation if needed.

March 2021: The MS2field returns to the field!

Recently we started the field campaign for a project with the aim to study pollutant dynamics in karstic springs in the Swiss Jura. Since these springs are frequently used as drinking water resources, maintaining a high water quality is crucial. The oftentimes characteristic fast hydrologic connection between the surface and karstic springs could hence result in the occurrence of concentration peaks of organic micropollutants. Here, the MS2field comes into play: Through temporally highly resolved measurements, we hope to observe whether abrupt changes in concentrations due to precipitation events occur or not. Therefore, since the end of March 2021 we placed the MS2field directly at one of three chosen springs located in the Swiss Jura. The three study sites chosen for an ongoing investigation were identified based on the careful evaluation of several criteria including e.g. a monitoring campaign conducted at 10 sites in the Swiss Jura from April to October 2020.

Eventually, we will learn about temporal dynamics of pesticides and their transformation products in karstic aquifers, which will help to make decisions on how to monitor the water quality and manage agricultural practices in these vulnerable environments.

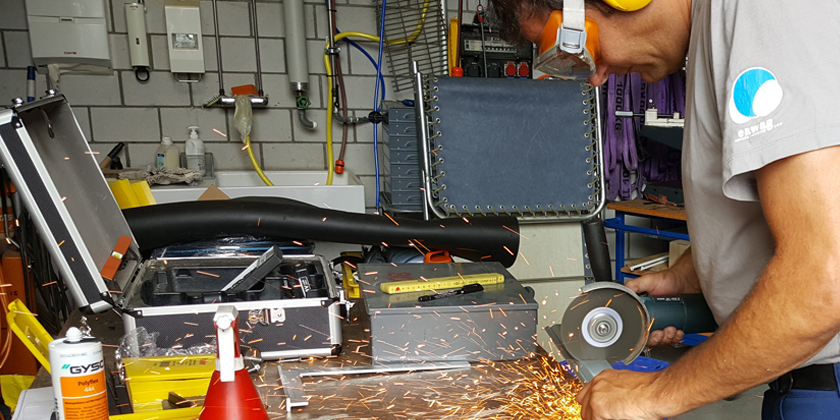

Pimp my trailer - Upgrade MS2field

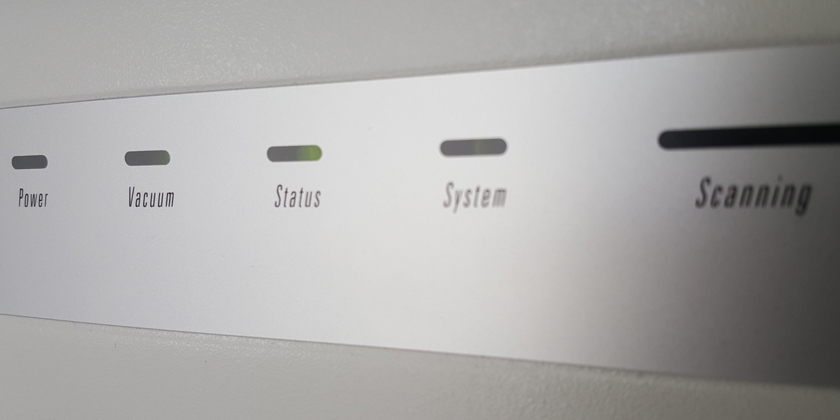

December 2020. To enlarge the scope of application of the MS2field, we equipped it with a clean water cycle. This allows us to dramatically reduce the risk of clogging when pumping raw wastewater from the sewer, which will be needed in the mikroMISCH project. With a 500 liter water tank and two valves we now are able to flush the bypass with clean water and also to fill the intake with water for better suction. Since continuous pumping from the sewer during dry weather will be challenging (high risk of clogging), we further installed a radar-level sensor to automatically start measuring when the water level rises and to stop measuring during dry weather.

In addition, we upgraded the MS2field with further sensors: pH, temperature and conductivity can now be measured continuously in the effluent of the bypass.

Dynamics in the effluent of a WWTP

October-December 2020. After a summer of upgrades and testing, we were eager to get the MS2Field out in the field again. However, before leaving for the field campaign, Andri Bryner and Dean Shirley organized a video shooting and produced a fantastic short video report on the MS2Field, which you can watch below. In mid-October, we installed the MS2Field on a wastewater treatment plant (WWTP) as part of the project GalPro. Installing the tube to pump up samples from the 4 meter deep sewer shaft where the treated wastewater flows together was tricky. However, with the great support from the staff of the WWTP, this setup delivered us samples for 2 months without any disruption. Thanks to the live evaluation, everyone who was involved in the project could watch the interesting concentration dynamics of the measured compounds from home in almost real-time. This was especially interesting for the attached pharmaceutical industry and the team of Miriam Langer which simultaneously tested their online-biomonitoring system at the WWTP. Finally, just before Christmas we drove the MS2Field back to the Versuchshalle at Eawag for a well-deserved holiday.

Real world application III and End of Season

August - December 2019. The third field trip - the first by contract - took us to St-Ursanne, 140 kilometers away from Eawag. Our crew set up the trailer in pouring rain and was ready after two half days. With Ann-Kathrin as new team member and with the support by the canton Jura, the MS2field operated over two months measuring the water quality in the Doubs. Overall, our unit processed almost 10,000 (ten thousand!) samples this year, with minimal wear and tear. The end of season we celebrated with a demo at the Treffpunkt Science City (ETH Zurich) with many enthusiastic visitors and with a photo shooting at Eawag. Stay tuned, we do not hibernate!

Real world application II

June 2019. A 70km-drive away from home, our mass spectrometer now measures the water quality in a small creek, directly in the field – our dream became true: “MS to field”! Again, the journey did not cause any problems and the unit was ready within a day. Sometimes, we fight with occasional difficulties of the bypass pump to provide a continuous sample stream reliably – in the next hardware update, we have to solve this issue.

Real world application I

February - May 2019. With excitement, we started our first journey! Despite a few kilometres on the road, there were no incidents and the trailer was set up within half a day, ready to measure after the bake-out. Particulate matter in the raw wastewater caused recurring problems with the bypass pump, which we solved with an optimized, automated back-flushing routine. Subsequently, measurements ran smoothly and the remote process control interface that we implemented proved to be extremely helpful.

During this deployment, our unit measured almost 2000 raw wastewater samples, originating from before and after the sand trap in the wastewater treatment plant’s influent. This implied bi-weekly cleaning, particularly of the filter unit. You can follow Michele during one of his typical maintenance days in Fehraltorf on higgs (German, with embedded Instagram posts in English) – thank you also Philipp and Benedikt for your support.

The subsequent analysis of treated effluent required almost no maintenance and we felt the automated measurements could have continued forever. We thank the open-minded, friendly staff from the wastewater treatment plant Fehraltorf for having hosted our first real-world application, and the urban water observatory team for their continued engagement.

A first evaluation of over 30 target compounds in the influent revealed almost as many distinctly different temporal patterns; thank you Pascale for your tremendous work during your semester thesis together with us. While some of these patterns observed at 20-minute resolution are plausible, others were really unexpected. Many of us probably would have struggled in accurately drawing a typical predicted pattern at this temporal resolution for most substances. We are looking forward what the non-target analyses will reveal …

Field test

December 2018. We achieved another milestone: we can now operate our mobile unit for the first time in the (almost) ‘final’ setup in the real world. Surprisingly(?), the inlet, pipe and pump to deliver the source water into the trailer requires most attention … our running gag is “It seems easier to pump ions through an Orbitrap than pumping water into the trailer”. At least no driftwood got caught at the inlet pipe in the creek (see animated sequence below).

Short sequence with driftwood dummy:

Finishing off & roll out

November 2018. Electrical wiring of sensors, checking the PLC (programmable logic controller) connecting everything and coding rules took most of the time this month. On Friday 24 November, we celebrated the roll out (see video below). We are again very thankful for the continued support by Richi, Marco and Marc (installation solutions), Adriano (PLC), Mathias and Christian (IT and electronics) and Andy, Seba and Kay (workshop) and many others. Thank you guys for your availability and providing so promptly all the big and small things we ask for!

Short video of the roll out:

Transfer to trailer

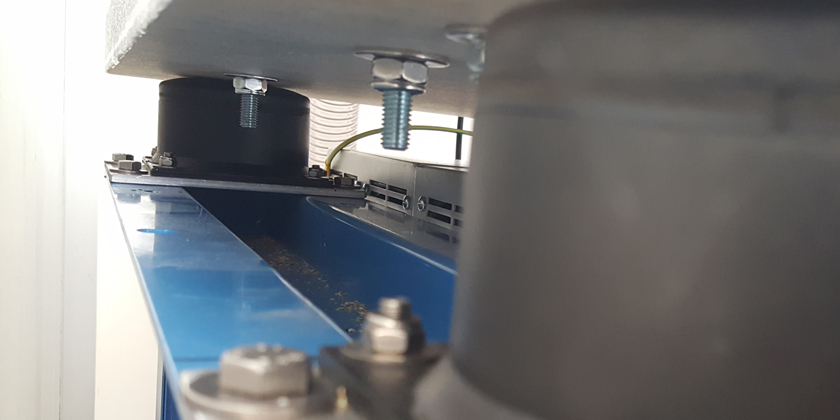

October 2018. We thought we had thought of everything. For a variety of issues we had to think and rethink multiple times to find practical and robust solutions:

- On the one hand, everything needs to be fixed and tightened to not move while driving.

- On the other hand, how to make all parts easily accessible for maintenance, e.g. the filtration device in the source water bypass?

- How to facilitate appropriate heating and cooling?

- How to guarantee a safe atmosphere inside the trailer (solvents, nitrogen generator)?

- How to prevent flooding of the trailer in case of pipe burst, or avoid the latter?

- How to guarantee power supply and remote control of all safety relevant components?

- How to minimize impact of vibrations?

We are enormously thankful for the support we received from our colleagues internally (many technical solutions and advice on design of remote control) and externally (plumbing and electricity)!

Now the MS is operating in the trailer and we are performing first prolonged measurements on water from the nearby creek (Chriesbach).

Short making-of video:

First success

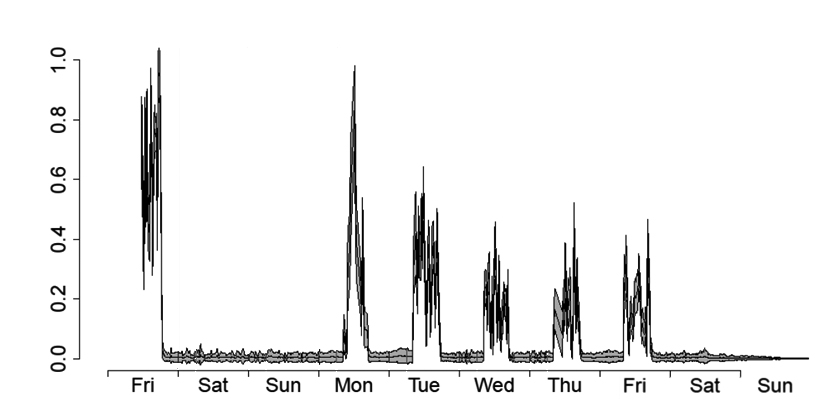

May 2018. In March and April, we carried out more preliminary tests and optimized the sample preparation. And most recently, the system succeeded in measuring more than 500 samples over a one-week period – one every 20 minutes – with minimal human interaction, resulting in a dataset of 500 raw files (35 GB, 2 x 10e6 scans). Pre-processing (peak picking and alignment) resulted in 90,000 time series that we evaluated with spectral analysis (periodograms). We identified approx. 50 interesting clusters. One example is a set of 38 profiles that show a distinct diurnal pattern MON-FRI but do not occur on SAT and SUN.

Assembling parts

February 2018. The MS arrived in January. We assembled all required components in our experimental hall and tested the new workflow with “primary clarifier effluent”. Six months after the project start and just one month after the instrument arrived, we have a basic setup that seems to fulfil our requirements: a powerful pump to deliver a sample stream, a robust filtration unit, a versatile sample preparation unit, different options for front ends and a laboratory mass spectrometer that seems to cope well with conditions that are more variable than in a normal laboratory. Now we are performing first measurements with real sewage (“sand trap effluent”) and are looking for a suitable trailer.

First three months

November 2017. Project start in September 2017! Many small details that are not an issue or easy to solve in a laboratory, require special attention and special solutions when aiming for operating an unattended system in a remote location over an extended period.

Our vision

2016/17. Wouldn’t it be interesting to measure a broad suite of micropollutants at high temporal resolution to better understand their occurrence and fate? Do you know a system that can take hundreds of samples a week for multiple weeks, and do you have the capacity to analyse them in a lab? We don’t.

Therefore, we seek collaboration with industry partners and apply for discretionary funding. Together with Thermo and CTC, our ambitious goal* is to measure micropollutant concentrations at intervals of minutes to hours, and quantify them directly in the field – with the same, high quality as traditionally in the lab.

* A goal is a dream with a deadline - Napoleon Hill (1883-1970), author in the area of the new thought movement, one of the great writers on success.

Duration

September 2017 - August 2019

Financing

Eawag - Discretionary Funding