Blue Diversion Autarky – Wastewater Treatment off the Grid

Autarky at a glance

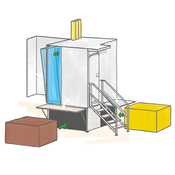

The Blue Diversion Autarky toilet is a sanitation system which provides hygiene and comfort without relying on water and wastewater infrastructure. Water, urine and feces are collected separately and treated on site in specific modules. The Blue Diversion Autarky toilet recycles water for hand washing and flushing, recovers nutrients for fertilizer production and inactivates pathogens reliably. The treatment modules can be replaced, integrated in other sanitation systems or used as stand-alone units. One example is the hand washing station, which was also developed by the Blue Diversion Autarky team.

Blue Diversion Autarky was launched in the context of the “Reinvent the Toilet Challenge” funded by the Bill & Melinda Gates Foundation. The project is currently in its second project phase. Blue Diversion Autarky is the continuation of the Blue Diversion project.

Guiding principles

Safety & comfort

The Blue Diversion Autarky toilet offers the safety and comfort of a modern flush toilet without requiring piped water or sewerage.

Source separation

Pathogen inactivation, nutrient recovery and water recycling for flushing and hand washing are achieved by the separate treatment of feces, urine and water.

Modularization

A modular design allows for a wide range of applications. Single modules can be used alone or combined with other technologies. One example is the stand alone hand washing station.

Research at a glance

The Blue Diversion Autarky system is based on the separate treatment of water, urine and feces. The core process for the water treatment is a gravity-driven membrane (GDM) filtration. After post-treatment in the form of an activated carbon filter and an electrolysis unit to remove microorganisms, the same water can be reused for flushing and hand washing. Urine is pretreated to eliminate malodor and pathogens, as well as to avoid the loss of nutrients. The volume of urine is then reduced by evaporating the water. The product is a concentrate of organic and inorganic nutrients, that can be used as fertilizer. The treatment of the feces is based on hydrothermal oxidation (HTO). Using high temperature and pressure, the feces are mineralized to carbon dioxide, water and precipitated inorganic solids.

We recently field-tested the Blue Diversion Autarky toilet in a 14-people household in a peri-urban zone of Durban, South Africa.The toilet system functioned well and the recycled water was readily used. As the adoption of new sanitation technology does not depend on the technical functionality alone, the testing was closely accompanied by a team of social scientists. The results of our socio-technical assessment and a detailed evaluation of the water treatment system are available throughopen access publications (see below).

Publications

More about water treatment

The water treatment system, referred to as Water Wall, recycles hand washing water, toilet flush water (separated from the major part of urine and feces), or both. A multi-barrier approach with four treatment stages ensures that the water is safe for reuse.

- The first barrier and core of the treatment is an aerated bioreactor, in which microorganisms degrade contaminants such as soap, urine, and feces.

- As the second barrier, the water is then filtered by gravity through an ultrafiltration membrane. The membrane pores are smaller than the size of bacteria and most viruses, providing water that is microbiologically safe after filtering through the membrane.

The combined biological treatment and membrane filtration without cleaning will produce a biofilm on the membrane. This effect is desirable in a gravity-driven membrane (GDM) approach, as the biofilm also contributes to the removal of organic carbon. The GDM system achieves approximately 95% removal of organic carbon.

The filtered water is stored in a clean water tank. Additional treatment is required to limit regrowth of pathogens and potential contamination.

- The third treatment barrier, an activated carbon filter, removes remaining organic contamination in the clean water tank by adsorption.

- Finally, the fourth and last barrier, an electrolysis unit, further reduces organic carbon concentrations and produces a chlorine residual, both of which help to limit pathogen growth during storage.

Current activities

With this setup, we were able to develop a small series of Water Wall prototypes for treating and recycling hand washing water or toilet flush water. These prototypes were extensively tested under laboratory conditions, under which they reliably removed pathogens, nutrients, malodor, and color from recycled water. However, when moving outside the laboratory, we expect a much higher variability of the number of users, composition of the water and external conditions. This is why we are currently exposing different configurations of the Water Wall to real-life conditions.

Update: our results from field tests in Switzerland and South Africa have now been published. The open access publication can be found here: https://doi.org/10.1016/j.wroa.2020.100051.

A Water Wall as part of a complete toilet system. The biological treatment takes place in the lower tank, with the ultrafiltration membrane sitting on the bottom of the tank. The activated carbon filter and the electrolysis unit are located in the upper tank.

Publications

More about urine treatment

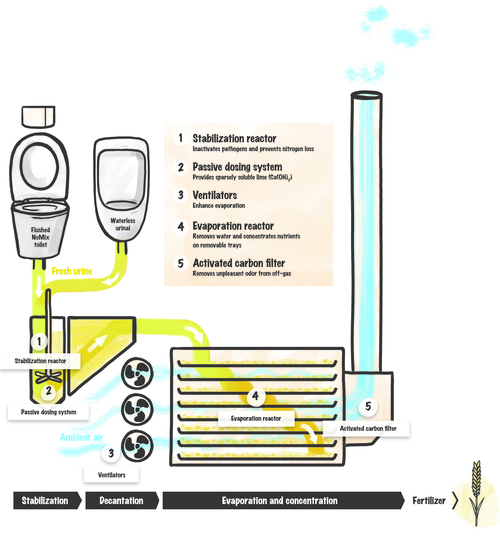

Two processes are necessary to treat the source-separated urine in the toilet: urine stabilization and water removal.

The main goal of the Autarky urine stabilization is the prevention of urea hydrolysis, a process converting urea to volatile ammonia and carbon dioxide. Through the addition of calcium hydroxide to fresh urine, the pH increases to values above 12 and thus prevents microbial urea hydrolysis.

Additionally, the high pH kills pathogens and prevents biological processes that produce malodor. When calcium hydroxide is added to the urine only about the amount dissolves that is needed to reach the necessary high pH value. This allows providing a depot of the reagent in the stabilization reactor; thus, no expensive and complicated dosage mechanisms are required. Moreover, calcium hydroxide, also known as hydrated lime, is a cheap reagent and readily available worldwide.

The direct application of human urine as fertilizer is a common practice in many rural areas around the globe. However, the high water content of urine – no matter if stabilized or not – requires significant storage capacity and can make the collection and transport to the agricultural fields very costly. Volume reduction does not only reduce costs for storage and transport, but could also facilitate field application of the concentrated fertilizer. Standard volume reduction techniques are most often energy intensive processes, because they require high temperature (distillation) or pressure (reverse osmosis).

Offering an alternative to these processes, our approach uses forced convection to reduce the volume of the urine. The evaporation reactor consists of a stacked tray system to create a large surface area. Fans generating a high air stream accelerate the evaporation of the the water from the incoming urine. The offgas is filtered through an activated carbon filter, preventing the emission of organic contamination or malodour.

Once a month, the system needs to be serviced. Tasks are to refill the calcium hydroxide depot and to harvest the trays. The remaining end-product is a concentrate of inorganic and organic nutrients that can be used as fertilizer in agriculture.

Current activities

The stabilization and evaporation reactors have been subject to extensive testing. These tests were supported by lab tests of specific parts of the reactors and a computer model simulating the system. Based on the collected information, the two reactors underwent a major redesign, allowing for an increased evaporation efficiency along with reduced overall size. Another focus of the redesign was the integration of service appliances, e.g. for harvesting of the produced nutrient concentrate.

To validate the technic in real-life settings several field tests of one to four months were conducted. The urine module was tested as part of the Autarky toilet system at Eawag campus in Dübendorf (Switzerland), as well as in a large family household in a Durban Township (South Afrika). As an individual entity, field tests of the urine module took place attached to a mobile Tinihouse (Au, Switzerland) and on a mountain hut (Leglerhütte, Switzerland).

Update: Technical details and everything about the field tests can now be found in our latest publication (open-access): https://doi.org/10.1016/j.wroa.2021.100124

Publications

Decrey, L., and Kohn, T. (2017) Virus inactivation in stored human urine, sludge and animal manure under typical conditions of storage or mesophilic anaerobic digestion. Environmental Science: Water Research & Technology.

Antonini, S., et al. (2012). "Solar thermal evaporation of human urine for nitrogen and phosphorus recovery in Vietnam." Sci Total Environ 414: 592-599.

Pahore, M. M., et al. (2010). "Rational design of an on-site volume reduction system for source-separated urine." Environ Technol 31(4): 399-408.

More about feces treatment

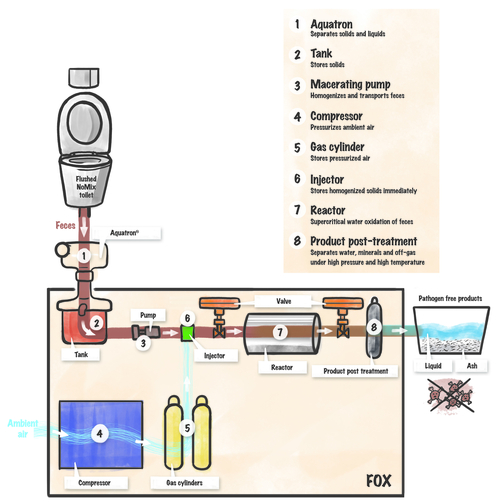

In the Blue Diversion Autarky toilet, the feces are separated from the flush water and collected in a container at the bottom of the toilet. They may contain pathogens and must be inactivated quickly to avoid anaerobic decomposition and the emission of malodorous gases.

Contact

In our approach, the organic matter of the fecal sludge is completely mineralized to carbon dioxide, water and minerals such as phosphate salts. The remaining streams are off-gas and a mixture of water and minerals. The off-gas contains mainly nitrogen, carbon dioxide and oxygen. This mixture can be safely vented to the atmosphere. The aqueous stream may be utilized as a fertilizer.

The process used to treat the feces is called “hydrothermal oxidation” or HTO. When mixed with air and heated above around 400°C under high pressure, the fecal sludge decomposes and is oxidized completely to carbon dioxide and water. The water in the sludge does not evaporate but mixes with the air and provides a reaction environment for an efficient conversion of the organic matter within a few minutes.

Current activities

For a better understanding of the HTO process, we are developing a comprehensive computer model of the reactor. This computer model is fed with data from experiments carried out in small autoclaves with real fecal sludge. We determined that the oxidation reaction is rapid above around 300°C and runs to completion within only a few minutes at 400°C.

We are currently improving the third prototype generation of the so-called FOX reactor (short for feces oxidation). This reactor will be field tested with real users soon. We are also working on the design of a more compact version of the FOX reactor, so it can be tested as part of the complete Blue Diversion Autarky toilet in the future.

Publications

Hübner, T.; Roth, M.; Vogel, F. (2016). Hydrothermal oxidation of fecal sludge: experimental investigations and kinetic modeling, Ind. Eng. Chem. Res. 55 (46), pp.11910-11922

Mangold, F.; Pilz, St.; Bjelić, S.; Vogel, F. (2019). Equation of state and thermodynamic properties for mixtures of H2O, O2, N2, and CO2 from ambient up to 1000 K and 280 MPa. The Journal of Supercritical Fluids, Volume 153, 104476

Team

The Blue Diversion Autarky team consists of researchers and experts from the Swiss Federal Institute of Aquatic Science (Eawag), the Paul Scherrer Institue (PSI), the University of Applied Sciences and Arts Northwestern Switzerland (FHNW) and from EOOS. The project is supported by an advisory board of six international commercial partners. Funding is provided by the Bill and Melinda Gates Foundation (BMGF).