Department Process Engineering

Gravity-Driven Membrane (GDM) technology

Inadequate access to microbiologically safe drinking water continuously threatens the health and well-being of more than a billion people, primarily in developing countries. In many areas worldwide the central water infrastructure is not available at all, or not reliable, leading to unsafe water at the tap. In such cases, decentralized water treatment can be used.

Ultrafiltration is an effective technology to treat water and in principle can be applied on a decentralized scale. Most ultrafiltration membranes have pores which are smaller than the size of bacteria and viruses. Thus, water filtered through these membranes is microbiologically safe.

During dead-end ultrafiltrtion all macro- and microorganisms, particles and colloids accumulate on the membrne surface and a fouling layer is formed. Backflushing or chemical cleaning are usually used during conventional ultrafiltration to remove fouling layer. This prevents the membrane from clogging, which is expected to occur during filtration on a long term. However, backflushing or cleaning results in complex and maintenance-intensive systems, which are difficult to operate on a long term in developing countries.

New releases

Research

Formation of biofilms on membrane surfaces is usually considered to be detrimental as filtration performances are decreased. However, controlling the formation of biofilms remains challenging and requires a significant energy- and chemical- demand. Our research aims at developing a new paradigm for operating membrane systems that consists in taking advantage of the presence of biofilms on membrane surfaces. The formation of biofilms on membrane surfaces indeed helps to stabilise the permeate flux over several month. The feed water composition determines the physical and biochemical structure of the biofilms, and ultimately its hydraulic resistance. The biofilm also helps to increase the permeate quality. The retention of biodegradable compounds or viruses is higher in the case of a "biofilm+membrane" composite system than for systems based on membrane only.

Hydraulic resistance of biofilms

Several factors influence the hydraulic resistance of biofilms formed during GDM filtration and in turn the permeate flux: the feed water composition in terms of (i) substrate concentration and (ii) microbial diversity and (iii) the operating conditions in terms of external forces acting on the biofilm structure (e.g. TransMembrane Pressure). These factors determine the physical and biochemical structure of the biofilms and ultimately its hydraulic resistance, i.e., the quantity of water that is filtered. Stable permeate flux of 5 to 20 L m-2 h-1 are usually observed during GDM ultrafiltration of surface water.

An increasing substrate concentration in the feed water results in a higher biofilm accumulation and in a lower flux. However, our results indicate that flux stabilisation always occurs, whatever the type of feed water: contaminated drinking water, surface water, used wash-water, etc.

Effect of predation

Predation by metazoa and protozoa improves the performance of membranes used for the filtration of contaminated water. Membrane filtration allows to securely remove most pathogens from contaminated water but efficient application of membranes is hampered by the development of biofilms on the surface of the membrane reducing the water flux. Strategies available to reduce biofilms on membranes are mostly energy and chemical intensive and lead to increasing operating costs. In our work we are developing an innovative approach that relies on biological mechanisms influencing the permeability of the biofilm to maintain water flux rather than chemical cleaning or energy intensive cross-flow.

Membranes are operated at low pressures and in a dead-end mode. Without mechanical stress a porous and heterogeneous biofilm structure develops that is susceptible to predation by higher organisms. In presence of predators (upper panel in Figure), an open and heterogeneous biofilm structure developed with only partially coverage of the membrane surface (85%). In absence of predation (where higher organisms are chemically inhibited, lower panel in Figure) a flat and compact structure covering the whole membrane surface developed. We were able to demonstrate that metazoa (rotatoria, nematoda, and oligochaeta) were the main group of higher organisms responsible for the development of open biofilm structures.

Towards lower footprint and capital costs of GDM systems

GDM is a relevant and adequate approach to produce safe drinking water due to low operation requirements and marginal need for external energy inputs. An important advantage of GDM is that these systems decrease the concentration of biodegradable compounds in the permeate, in comparison to conventional ultrafiltration (UF). These characteristics are not only of major interest for community scale systems, but also for centralized systems. For instance, enhancing the removal of biodegradable compounds is one of the first objective of reverse osmosis pre-treatment step, given that they are major membrane foulants. Yet, a principal limitation for GDM applicability in centralized systems is the higher footprint and associated capital costs caused by higher membrane surface requirements, due to lower fluxes than achieved with conventional UF.

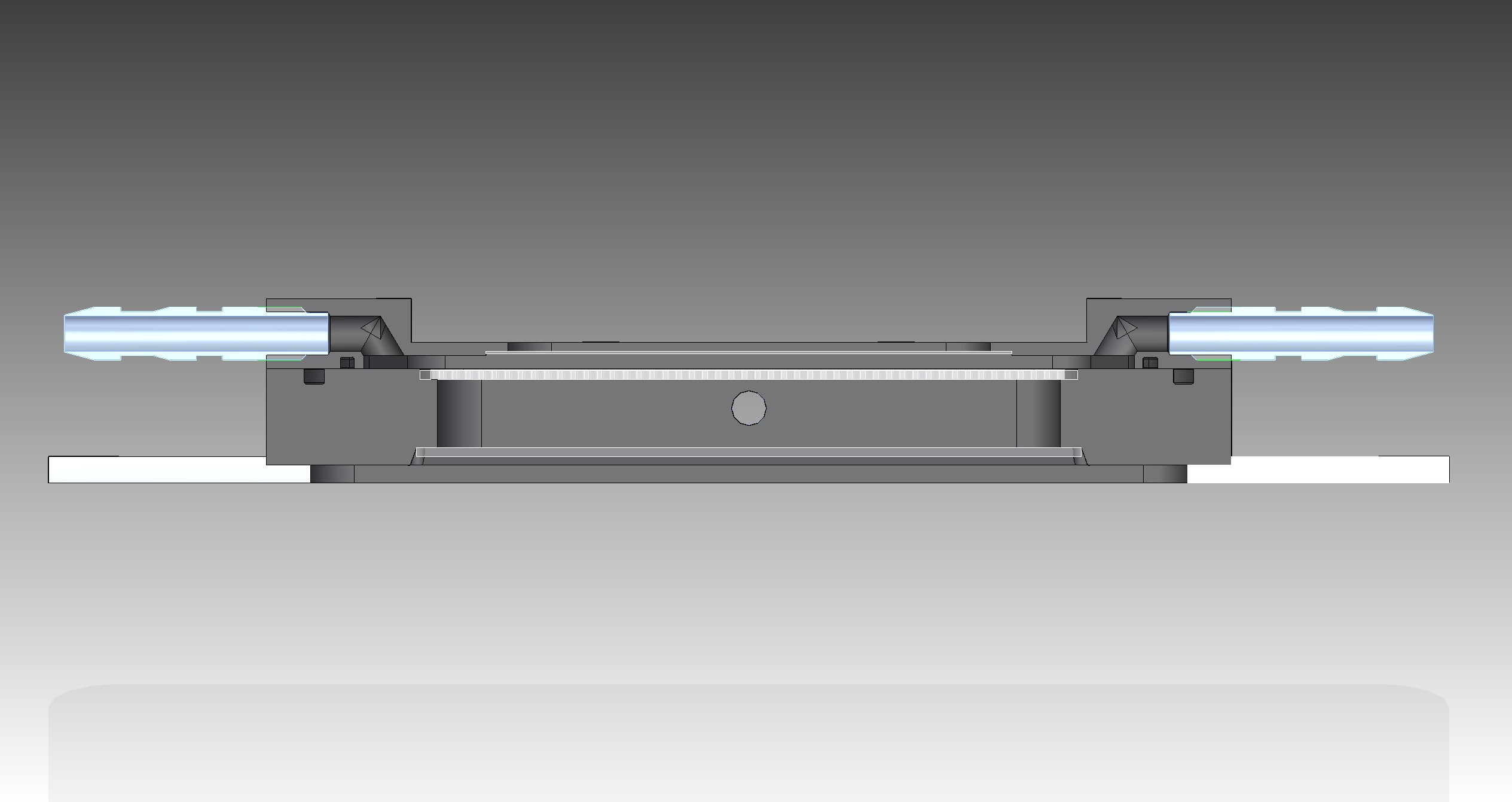

Since 2019, we actively work on approaches that could increase GDM fluxes and reduce space requirements by replacing flat-sheet with hollow fiber membranes. Using our new GDM platform (picture), we successfully proved that GDM filtration is feasible with hollow fiber (HF) membranes operated in inside-out mode. The implementation of a backwash allows maintaining high fluxes despite the low space availability for biofilm growth in the lumen of the fibers, as discussed in Stoffel et al., (2021). With this project, we showed that the GDM step footprint could be decreased by up to 20 times, when implementing HF membrane operated in inside-out mode with low cost maintenance instead of GDM systems equipped with non-maintained flat sheet membranes.

Our current activities focus on assessing procedures to lowering the capital costs and optimizing the operation.

Blue Diversion Toilet (Reinvent The Toilet Challenge)

In 2011 the Bill & Melinda Gates Foundation initiated and funded the competition "Reinvent-the-Toilet-Challenge" (RTTC) in which eight universities with promising entries had to proof their concepts. The target is to develop a mass-produced sanitation system operating grid-free (not connected to electricity grid, piped water, or sewer) with total costs not exceeding 5 US cents per person and day. High user comfort and total resource recovery are also key requirements.

Almost 2.6 billion people worldwide use unsafe toilets or defecate in the open. Poor sanitation causes severe diarrhea, which kills 1.8 million people each year. This problem is especially daunting in dense urban settlements especially affecting the urban poor. Therefore people living in under such conditions are the target group for RTTC.

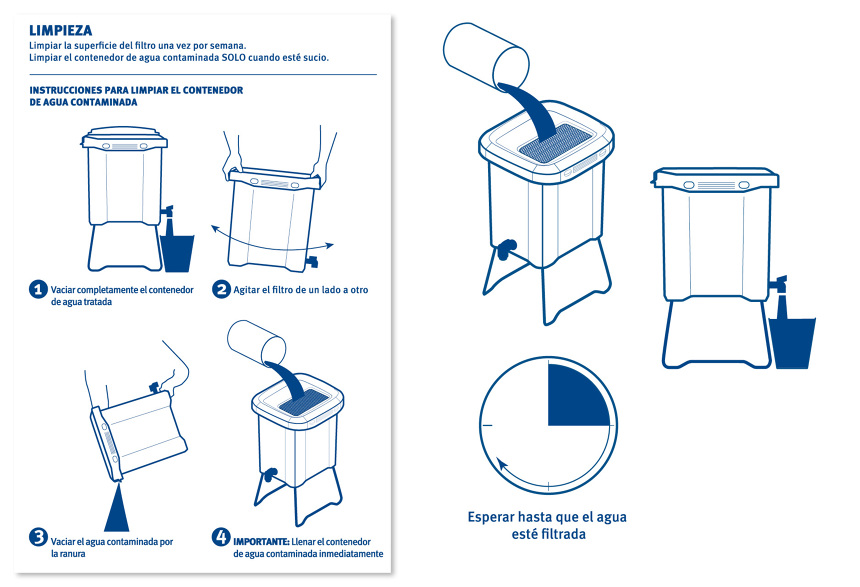

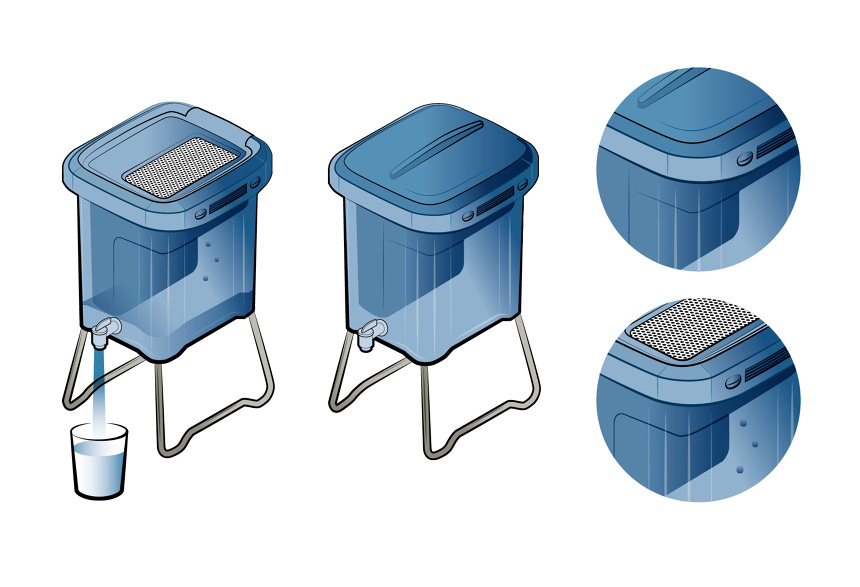

A key feature of the toilet system developed in collaboration with the Austrian design office EOOS is an on-site water recovery system which is based on gravity-driven ultrafiltration and is integrated in the back wall of the toilet. GDM filtration is applied in the RTTC project to the recovery of wash and flush water. The special feature of the gravity-driven ultrafiltration is its passive biological activity maintaining the membranes permeable, thus making chemical cleaning or maintenance unnecessary as long as moderate aeration is provided.

More information about this project

Publications associated

- Larsen, T.A., Gebauer, H., Gründl, H., Künzle, R., Lüthi, C., Messmer, U., Morgenroth, E., Niwagaba, C.B., Ranner, B. (2015). Blue Diversion: a new approach to sanitation in informal settlements. J. Water Sanit. Hyg. Develop., 2015, 5(1) 64-71.

- Ravndal, K., Künzle, R., Derlon, N., Morgenroth, E. (In Press). On-site treatment of used wash-water using biologically activated membrane bioreactors operated at different solids retention times. J. Water Sanit. Hyg. Develop.

- Künzle, R., Pronk, W., Morgenroth, E., Larsen, T.A. (In Press). An energy-efficient membrane bioreactor for on-site treatment and recovery of wastewater. J. Water Sanit. Hyg. Develop.

Other related projects

About us

Collaborators

- Thomas Neu, Head of group "Microbiology of interfaces", Department of river ecology, Helmholtz Centre for Environmental Research - UFZ.

- Judith Blom, Limnology Station of Zürich, University of Zürich.

- Jakob Pernthaler, Prof., Limnology Station of Zürich, University of Zürich.

Former members

- Richard Johnston, former Head of the water supply group (SANDEC).

- Maryna Peter-varbanets, former post-doc in the water supply group (SANDEC)

- Selina Derksen-Müller, former project officer in the water supply group (SANDEC).

- Anna Chomiak, former PhD student in the process engineering department

- Joao Nuno Maximino Mimoso, former PhD student in the process engineering department.

Downloads

PhD theses

Anna Chomiak (2015). Influence of inorganic and organic matter in gravity-driven membrane ultrafiltration. Diss. ETH no. 22669.

Maryna Peter-Varbanets (2010). Ultra-low pressure ultrafiltration for decentralized drinking water treatment. Diss. ETH no. 19134.

Presentations

Other publications

- Effizientes Recycling einer knappen Ressource: (Project „self“- self-sufficient house). Eawag Jahresbericht 2010

- SELF-media release, Eawag 2010

- Maryna Peter (2010) Ultra-low pressure ultrafiltration for decentrlized drinking water treatment. PhD thesis submitted to ETH Zurich

- Pronk, W., Peter-Varbanets, M., Schwerkraftgetriebene Ultrafiltration für die dezentrale Trinkwasseraufbereitung, GWA, 2010 (1) 19-22.

- Perron, S. Microbial regrowth in drinking water treated with gravity-driven ultrafiltration. (2011). MSc Thesis, Uppsala University, Uppsala.

- Erschreckende Wasseranalyse, Haiti 1 Jahr nach der Erdbeben-Katastrophe, Einstein, Schweizer Fernsehen, Sendung vom 06.01.2011.

- Job, F. C. End user Perception and Willingness-to-Pay for Gravity Driven Membrane Disinfection in Nakuru, Kenya. (2012). MSc Thesis, UNESCO-IHE, Delft.